Alloy Powder Cores are soft ferromagnetic cores made from ferrous alloy powders, after insulating , mixed pressed with in-organic binder then annealing in high temperature. Alloy Powder Core materials are pressed with an in-organic binder, so there is no thermal aging. Alloy Powder Cores are distributed air gap cores that are primarily used in power inductor applications, such as switched-mode power supply (SMPS) output filters, differential inductors, boost inductors, buck inductors, and flyback transformers. Alloy Powder Core materials are high resistivity, low hysteresis and eddy current losses and excellent inductance stability under both DC and AC conditions.

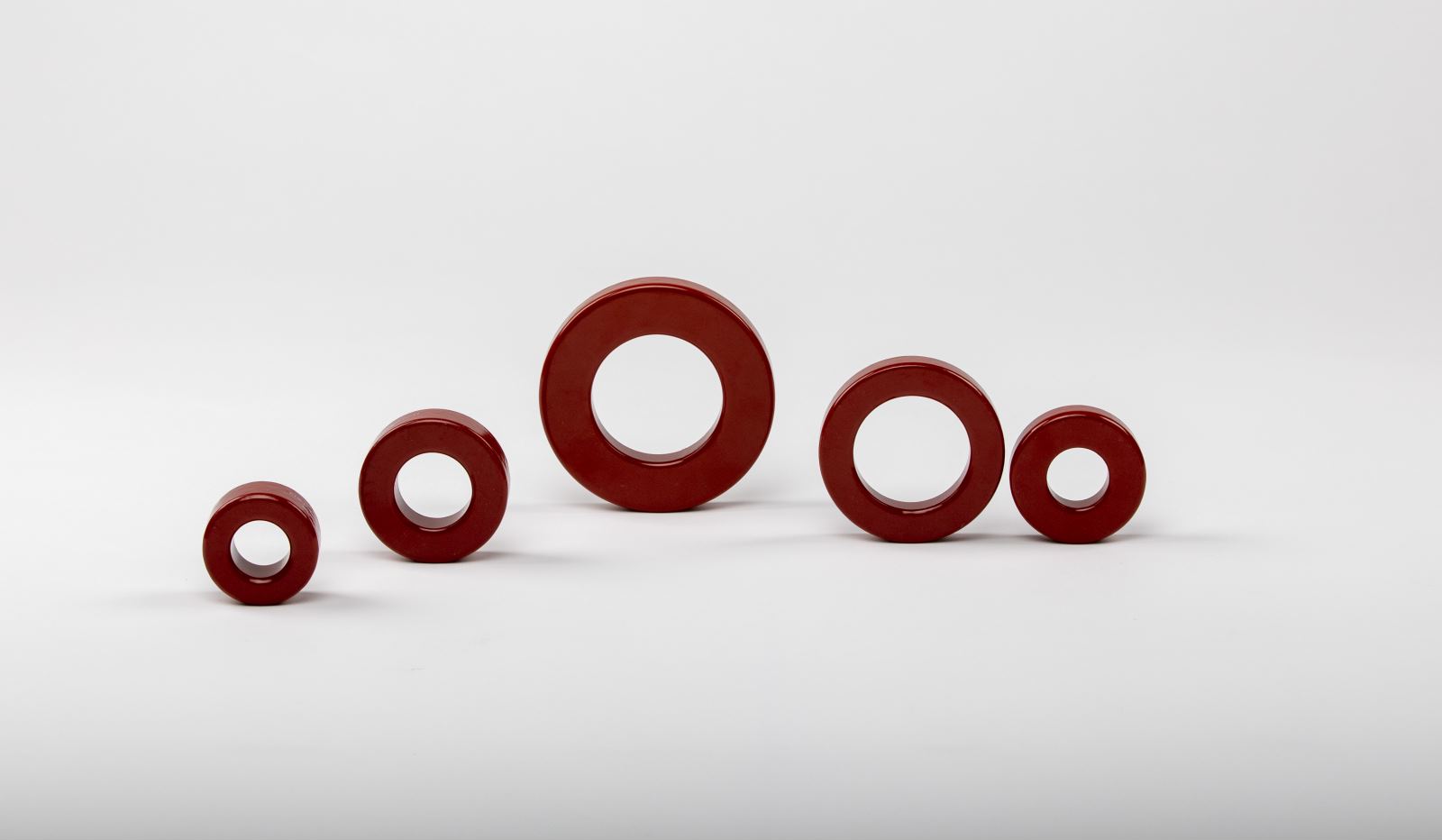

Iron Powder Cores

Iron powder core is a soft ferromagnetic material based on pure iron or carbonyl iron powder; mixed with binding material and pressed to form the surface is coated with insulation material. Iron powder core has a high magnetic flux density (14000Gs), so it will not be saturated under high magnetic field. It has a very good DC superimposed characteristic.

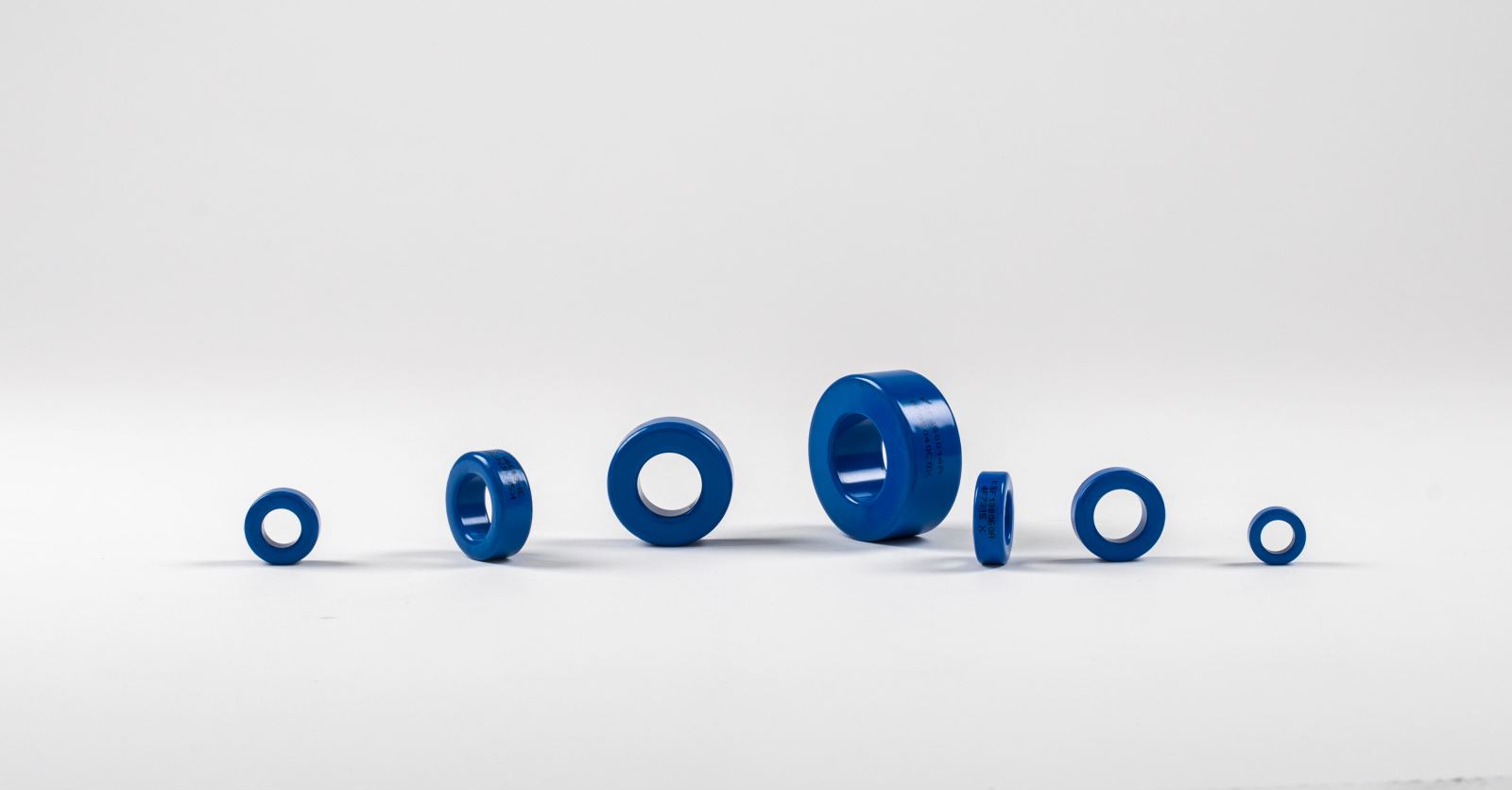

Toroidal Alloy Powder Cores

Alloy Powder Cores are soft ferromagnetic cores made from ferrous alloy powders, after insulating, mixed pressed with in-organic binder then annealing in high temperature. Alloy Powder Core materials are pressed with an in-organic binder, so there is no thermal aging. Alloy Powder Cores are distributed air gap cores that are primarily used in power inductor applications, such as switched-mode power supply (SMPS) output filters, differential inductors, boost inductors, buck inductors, and flyback transformers. Alloy Powder Core materials are high resistivity, low hysteresis and eddy current losses and excellent inductance stability under both DC and AC conditions.

Sendust Cores (KS)

Coating Color: Black

Main Features

- Lower Core Losses than Iron Powder Cores

- Near Zero Magnetostriction

- Relatively High Saturation Flux Density (10,500 Gauss)

Main Application

- PC Power Supply

- Power Adapter

- Uninterruptible Power Supply

- Active Power Filter/Static Var Generator

Si-Fe® Cores(KSF)

Main Features

- High Saturation Flux Density (16,000 Gauss)

- Excellent DC-bias Characteristics

- Excellent Thermal Stability Without Aging Problem

Main Application

- Industrial Power Supply

- PV Inverter

- Uninterruptible Power Supply

Coating Color: Blue

High Flux Cores (KH)

Coating Color: Khaki

Main Features

- Excellent DC-bias Characteristics

- High Saturation Flux Density (15,000 Gauss)

- Low Core Losses

Main Application

- Automotive OBC

- High Efficiency Sever Power Supply Communication Power Supply

Nanodust ® Cores (KAM)

Main Features

- High Saturation Flux Density (13,000 Gauss)

- Good DC-bias Characteristics

- No Audible Noise

- Core Losses are Closer to MPP Cores

Main Application

- High Efficiency Sever Power Supply

- Communication Power Supply

- Automotive OBC

Coating Color: Khaki

Super Sendust Cores (KS-HF)

Coating Color: Black

Main Features

- Good DC-bias Characteristics

- High Saturation Flux Density (12,000 Gauss)

- Low Core Losses

Main Application

- Industrial Power Supply

- PV Inverter

- Uninterruptible Power Supply

Neu Flux® Cores (KNF)

Main Features

- Lower Core Losses than Si-Fe® Cores

- High Saturation Flux Density (16,000 Gauss)

- Excellent DC-bias Characteristics

Main Application

- Industrial Power Supply

- PV Inverter

- Uninterruptible Power Supply

Coating Color: Brown

MPP Cores (KM)

Coating Color: Gray

Main Features

- High Resistivity, Low Hysteresis and Eddy Current Losses

- Lowest Core Losses

- Excellent Temperature Stability

Main Application

- Aerospace Power Supply

- Défense Power Supply

- Medical Power Supply

- High Efficiency Power Supply

Sendust Plus Cores (KPH)

Main Features

- Lower Core Losses than Super Sendust Cores

- Good DC-bias Characteristics

- Good Temperature Stability and Frequency Characteristics

Main Application

- Charging Pile

- PV Inverter

- Uninterruptible Power Supply

Coating Color: Black

High Flux Plus Cores (KH-H)

Coating Color: Kakhi

Main Features

- Lower Core Losses than High Flux Cores

- Good DC-bias Characteristics (%85μ0@100Oe)

- The Best Material for High Efficiency and High Power Density

Main Application

- Industrial Power Supply

- Communication Power Supply

- Automotive OBC

- DC/DC Converter

Alloy Special Shapes

KDM Powder Cores are available in a variety of geometries including toroid, E/EQ/HC shape, U shape, block shape and so on. Meanwhile, customized designs could be available upon request.

- EE Cores

- EQ Core

- EC Core

- UU Core

- Block Core

- Ellipse Core

- Cylinder Core